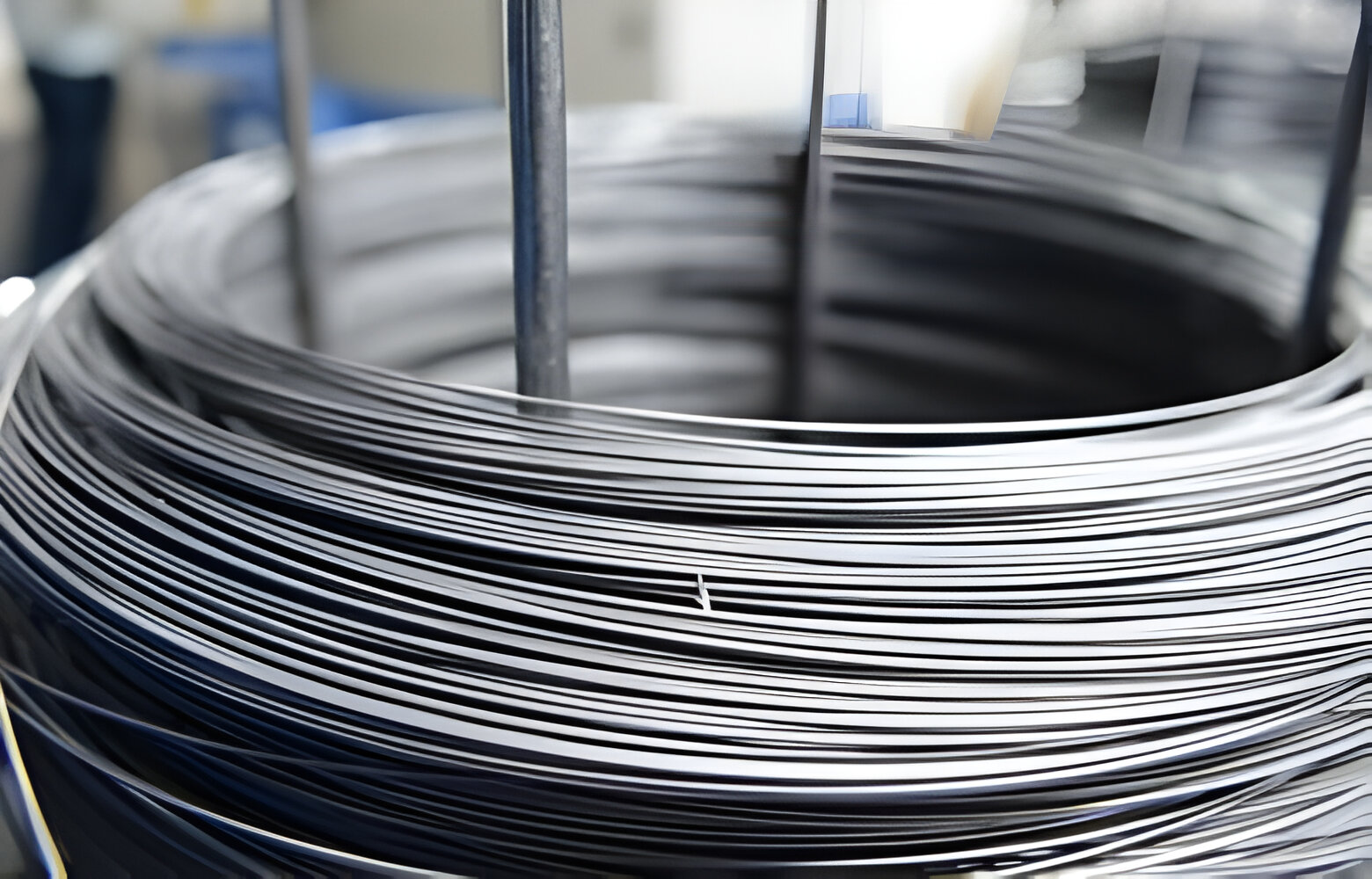

Our industrial quality wire rods are designed for non-critical applications where high formability and durability are essential. These rods are suitable for cold drawn parts and a wide range of products including nails, mesh, fencing, chains, paper clips, staples, baling wire, dishwasher and freezer racks, supermarket carriers, animal cages, small shaped products, and barbed wires.

Thanks to their excellent surface properties, our wire rods are also ideal for metal coating processes such as galvanizing and chrome plating. The adhesion of the metal coating to the wire rod surface ensures a high-quality finish suitable for various applications.

Our wire rods are available in various sizes and can be customized to meet specific requirements. Some of our low carbon drawing quality wire rods include grades such as C6D to C22D and SAE1006 to SAE1022.

Standards and Specifications

SAE1006 Standard:

SAE1006 wire rod is characterized by its low carbon content and excellent ductility, making it ideal for cold drawing and forming processes. This standard is particularly suitable for applications requiring high levels of formability.

Chemical Composition:

Carbon (C): 0.03-0.08%

Manganese (Mn): 0.25-0.45%

Phosphorus (P): ≤ 0.04%

Sulfur (S): ≤ 0.05%

Mechanical Properties:

Tensile Strength: 300-450 MPa

Yield Strength: 190-300 MPa

Elongation: ≥ 30%

SAE1008 Standard:

SAE1008 wire rod offers good weldability and moderate strength, making it suitable for a balance of strength and formability. It is commonly used in the production of industrial fasteners and wires.

Chemical Composition:

Carbon (C): 0.08-0.10%

Manganese (Mn): 0.30-0.50%

Phosphorus (P): ≤ 0.04%

Sulfur (S): ≤ 0.05%

Mechanical Properties:

Tensile Strength: 340-480 MPa

Yield Strength: 210-350 MPa

Elongation: ≥ 25%